Butterfly Damper Valve

Butterfly Damper Valve

Blog Article

Butterfly Damper Valve

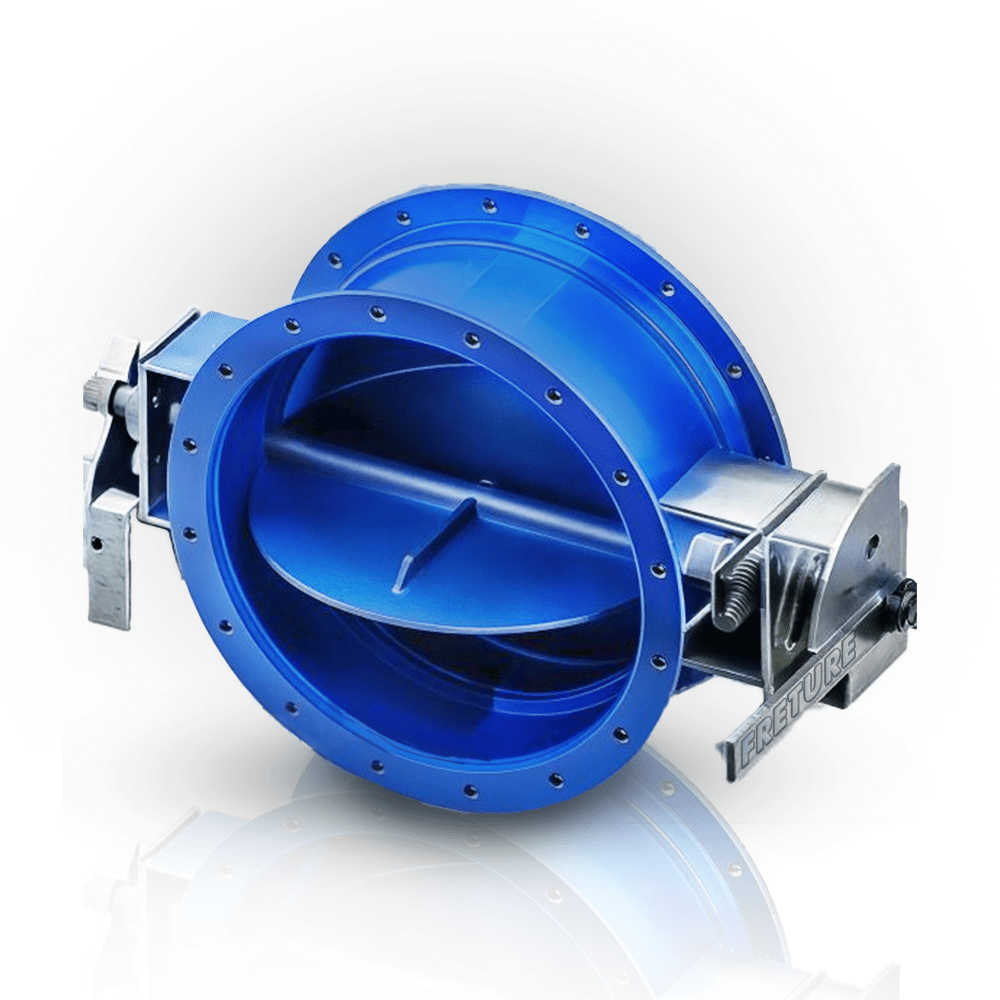

A butterfly damper valve is a critical component in air and gas flow regulation systems. Designed to offer compact, lightweight, and efficient control, this valve operates by rotating a disc to allow, restrict, or shut off airflow in a duct. It is primarily used in ventilation, dust extraction, flue gas, and combustion air systems. Known for their quick response and minimal pressure drop, butterfly damper valves are a preferred choice in industrial applications requiring consistent airflow management.

Working Principle of Butterfly Damper Valve

The butterfly damper valve operates using a centrally mounted circular blade (disc) that rotates around an axis perpendicular to the flow. When the disc is aligned parallel to the airflow, it permits maximum flow. As it rotates perpendicular to the duct, it gradually restricts or completely blocks the passage.

Actuation can be manual (via lever or gearbox) or automatic (using pneumatic, electric, or hydraulic actuators). The valve’s operation is smooth and responsive, enabling precise control of air or gas in low to moderate pressure environments.

Construction and Materials

Butterfly damper valves are typically constructed from robust materials to withstand varying temperatures and corrosive environments:

- Body: Mild steel, stainless steel, or galvanized steel

- Blade/Disc: Stainless steel or alloy steel

- Shaft: Steel or corrosion-resistant alloys

- Sealing Options: Metal-to-metal or resilient seals for leak-tight performance

- Actuation Mechanism: Manual, electric, pneumatic, or hydraulic

Types of Butterfly Damper Valves

Manual Butterfly Damper Valve:

Operated by hand levers or gearboxes, suitable for systems with infrequent adjustments.

Motorized Butterfly Damper Valve:

Equipped with electric or pneumatic actuators for automated operation, often used in HVAC and process industries.

Single Blade vs. Multi-Blade: Single-blade valves are used for basic flow control, while multi-blade variants are designed for larger ducts and more uniform airflow distribution.

Zero Leakage Butterfly Damper: Specially designed with enhanced seals for high-performance applications requiring complete shutoff.

- Key Features and Benefits

Compact Design: Requires less space compared to other damper types, making it suitable for tight installations. - Low Pressure Drop: Offers minimal resistance to airflow when fully open, enhancing system efficiency.

- Fast Operation: Rapid opening and closing due to simple disc rotation.

- Cost-Effective: Economical compared to louver or guillotine dampers, especially for moderate-duty applications.

- Versatile Actuation: Easily integrated with modern control systems for remote operation and automation.

- Durability: Built to withstand high temperatures, corrosive gases, and continuous duty cycles.

Applications of Butterfly Damper Valves

Butterfly damper valves are used in a wide range of industries where airflow or gas control is essential:

- HVAC Systems: For regulating and balancing air distribution in commercial buildings and clean rooms.

- Power Plants: Used in flue gas desulfurization, exhaust control, and heat recovery systems.

- Steel and Cement Industries: To manage hot and dust-laden gases in furnaces and kilns.

- Chemical and Petrochemical Plants: For handling process gases and ventilation air.

- Waste Incineration Units: Used to control combustion air and flue gases.

- Dust Collection Systems: Helps in isolating or diverting flow in bag filters and scrubbers.

- Installation and Maintenance Considerations

Orientation: Can be installed in horizontal or vertical ductwork depending on the system layout. - Accessibility: Should be positioned for easy access for inspection and maintenance.

- Leakage Control: Periodic checks are essential to ensure the integrity of seals and prevent air or gas leakage.

- Actuator Servicing: For motorized valves, actuators should be calibrated and serviced regularly for optimal performance.

Why Choose Butterfly Damper Valves?

Butterfly damper valves offer an ideal balance of efficiency, control, and reliability for air and gas flow management. Their lightweight design, coupled with quick actuation and low pressure drop, makes them especially suitable for energy-conscious operations and industrial systems demanding fast, responsive airflow control.

The butterfly damper valve stands out as a dependable solution for managing airflow in industrial ducts and process systems. Whether it's balancing air distribution in HVAC networks or controlling hot gases in power generation facilities, this valve type proves to be an essential tool in achieving operational efficiency.

Freture Techno Pvt. Ltd. is a trusted manufacturer of Butterfly damper valves in Mumbai, India, offering high-performance valves tailored to meet the specific needs of various industrial environments. Report this page